Maximum Allowable Moment

KFMIZUFIL (Permissible indexed torque for torque limitation before filter)

X axis : Accelerator pedal (%) 8 bit map with factor 0.390625. (wped)

Y axis: Engine speed (rpm) 8 bit map with factor 40. (nmot)

Z axis(map): (%) 8 bit map with factor 0.390625.

Output of KFMIZUFIL is corrected by maps KFDMINS,KLDMKH (temperature dependent friction loss and catalytic heating is considered) and the variable MDVERBZU_W and use the maximum value after comparing with constant MDIMX(here 99.219%). Final value after correction is mizuvfil_w.

Variable MDVERBZU_W is defined in subsection mdzul-nsc

Here mdverl_w – engine torque loss

mds_w- engine drag torque (torque required to rotate the crank without combustion)

fnstab_w – factor for stabilization using speed quotient.

nmot_w – engine speed.

mdverbzu_w– permissible torque requirement of the auxiliary units.

mizuvfil_w goes through a time constant low pass filter and become mizufil_w. This is the input variable for the map KFMIZUOF.

KFMIZUOF(Permissible indexed torque for torque limitation)

X axis: mizufil_w (%) 8bit factor 0.390625

Y axis : engine speed (rpm)

Z axis(map): mizuofil_w

Output of this map(KFMIZUOF) mizuofil_w is added to mizufil_w (filterd torque) and we will get miszul_w which is the maximum permissible indicated moment.

.

KFMIZUFIL and KFMIZUOF

Basic Ignition angle

Basic ignition angle is calculated from the map KFZW, map KFZW2 is used when camshaft control is active.

KFZW (Ignition angle map)

X axis: Engine speed(rpm) 16bit factor 0.25

Y axis: Engine load(%) 16bit factor 0.0234375 (rl)

Z axis: Ignition angle(grad KW) 8bit factor 0.75

KFDZWKG(Ignition angle correction by shifting the knock limit)

X axis: engine speed(rpm) 8 bit factor 40

Y axis: Basic lambda 8 bit factor 0.0078125 (lambas)

Z axis: KFDZWKG (grad KW) 8 bit factor 0.75

The out put from the map KFZW is corrected by adding the values from the map KFDZWKG and the variables dzwoag_w, dzwol_w to get the basic ignition angle zwgru_w.

Where dzwoag_w – Exhaust gas recirculation rate dependent ignition angle correction of the optimal ignition angle.

dzwol_w- lambda dependent Ignition angle correction of the optimal ignition angle.

Driver desired torque

Drivers desired moment is calculated in the module %MDFAW.

mrfgr_w – Relative torque requirement of FGR

mrfa_w – Relative driver desired torque from FGR and pedal

dmllri_w – required torque change from the LLR(idle speed control) (I component)

mdslw_w – Torque loss: charge change

mimax_w- maximum achievable indexed torque

mimin_w- Minimum engine torque

MDIMX- Maximum indicated engine torque

mivbeg_w – Indicated driver desired torque before change limitation

mifa_w- indicated engine torque driver request

mifal_w- Indicated driver’s desire moment by moment coordination filling

Drivers desired torque is calculated depending on accelerator pedal position(wped_w). Accelerator pedal characteristics are described in the maps KFPED.

KFPED (Relative driver desired torque from the accelerator pedal)

X axis: accelerator pedal position(%ped) 16bit factor 0.00152590219.

Y axis: engine speed(rpm) 16bit factor 0.25

Z axis: KFPED (%) 16bit factor 0.003051757812

mrped_w – Relative driver desired torque from the accelerator pedal

Lambda control

LAMFAW Lambda driver wish

The LAMFAW function uses lamfa_w to enrich the mixture when the driver demands maximum torque via mrfa_w

lamfa_w – Lambda target driver request (word)

During over boost in the turbocharger, an additional enrichment occurs by a delta lambda from the DLAMOB characteristic curve for the time TLAMFAS, enrichment beyond the driver’s request can be prevented as a function of the altitude

In the LAMKR subfunction, enrichment can be achieved during ignition angle interventions.

The LAMWL partial function can be used for enrichment during warm-up.

LAMFA (lambda driver wish)

X axis: engine speed(rpm) 8 bit factor 40

Y axis: mrfa_w (%) 16 bit HiLo (in damos it is given as 16bit LoHi, it is wrong please note) factor 0.003051757812

Z axis: lamfa (%) 8 bit factor 0.0078125

LAMBTS Lambda component protection

If the exhaust gas temperature is too high, it can be reduced by enriching the air-fuel mixture. This enrichment results in more fuel into the cylinder than would be necessary for stoichiometric combustion of the fuel. The unburned fuel evaporates on the cylinder walls and cools them, which also reduces the exhaust gas temperature

KFLBTS (Lambda target for component protection)

X axis: engine load (%) 16bit factor 0.0234375

Y axis: engine speed 8 bit factor 40

Z axis: KFLBTS 8 bit factor 0.0078125

Using the KFLBTS map, you can shift the lambda target towards rich depending on the engine speed and filling (engine load). The enrichment only takes effect when one of the modeled temperatures tabgm_w, tkatm_w, tikatm_w or twistm_w is in Subfunction LAMBTSENABLE exceeds its applicable threshold and the switch-on delay time TDLAMBTS + TVLBTS has expired.

tabgm_w – Exhaust gas temperature before catalytic converter from model

tkatm_w – Catalyst temperature from model

tikatm_w – Exhaust gas temperature in the catalytic converter from model

twistm_w – Cylinder head temperature from model [K] in vs100 visible in [degrees C]

TABGBTS – Exhaust gas temperature threshold for component protection 820.00 deg c

TKATBTS – Cat temperature threshold for component protection 1229.98 deg c

TIKATBTS – Temperature threshold in the catalytic converter for component protection 1229.98 deg c

The LAMKO lambda coordination function determines at which operating point the engine is operated. Basic lambda lambas_w is calculated from the priority of the different lambda interventions.

Cat protection has the highest priority, followed by component protection or driver’s request, cat evacuation and cat heaters.

The component protection for manifolds, exhaust valves and charger turbine are implemented via the inputs lambts_w

In normal operation, lambda target is specified by lamfa_w or lambts_w.

HFM plausibility check

KFMLDMX (ML threshold for B_maxflr diagnosis HFM/HLM)

X axis: wdkbadmx_w (%) ( throttle valve angle )16bit factor 0.0244140625

Y axis: engine speed 16bit factor 0.25

Z axis: KFMLDMX (kg/h) 16 bit factor 0.1

B_mxlm is set if (mlhfmm-MLOFS) greater than the speed and throttle dependent threshold value KFMLDMX

B_mxlm – Condition for max error main filling sensor

Mlhfmm- Air mass HFM average

MLOFS – Characteristic curve offset HFM

Knock detection

The knock detection thresholds are stored in maps based on the engine speed and load.

KFKEF (Knock detection factor map ignition)

X axis: engine speed(rpm) 8 bit factor 40

Y axis: engine load (%) 8 bit factor 0.75

Z axis: KFKEF 8 bit factor 0.0625

Output of the KFKEF is corrected by various factors and the final corrected knock detection threshold values is kek_w

If ikr/rkrmx is >= kek the condition for detected knock (b_kl) become true.

Where ikr – Integrator value knock control offset corrected

rkrmx – upper-limited reference level (rkmrx is calculated from the maps RKRMX1N and RKRMX2N).

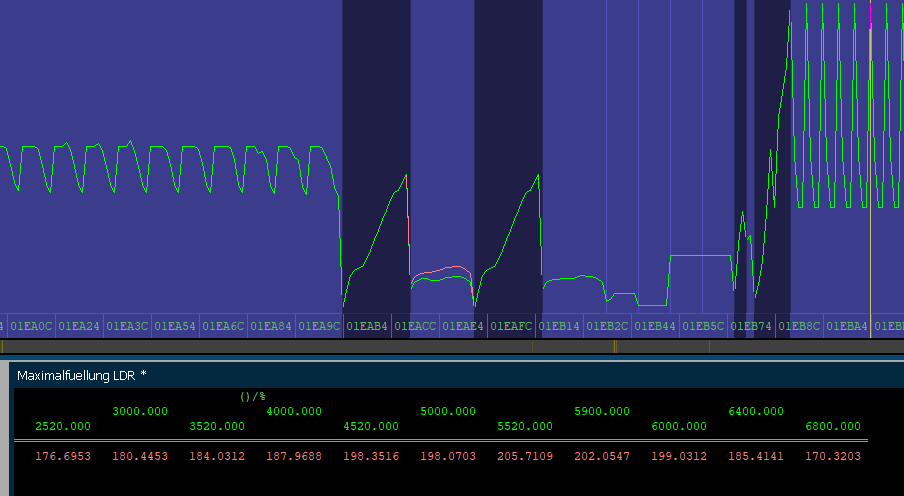

Calculation of maximum filling

The LDRLMX function calculates the permitted maximum filling rlmax_w.

Maximum specified load ldrxn

Maximum specified load is calculated from the maps LDRXN and LDRXNZK (during knocking).

LDRXN (Maximum filling LDR)

X axis: engine speed 16bit factor 0.25

Y axis: LDRXN 16bit factor 0.0234375

we don’t recommend to increase ldrxnzk map much

KFLDHBN (LDR height limit (max. compressor pressure ratio))

X axis: engine speed 8 bit factor 40

Y axis: Intake air temperature (Grad C) 8bit factor 0.75 (-48 offset)

Z axis: KFLDHBN 8 bit factor 0.015625

boost will follow LDRXN or KFLDHBN, whichever results in a lower requested load

rlmx_w from map LDRXN is corrected to rlmax_w by following maps.

KFFLLDE (Factor for slow boost pressure intervention on rlmax by KR (fuel))

X axis: engine speed 16bit factor 0.25

Y axis: WKRMSTAT_W (Grad KW) 16 bit factor 0.1875

Z axis: KFFLLDE 16 bit factor 0.000030517578

WKRMSTAT_W– Quasi-stationary average of the cylinder-specific ZW retard adjustment values

KFTARX (Map maximum filling Tans (intake) correction factor)

X axis: engine speed 16bit factor 0.25

Y axis: Intake air temperature (Grad C) 8bit factor 0.75 (-48 offset)

Z axis: KFTARX 16 bit factor 0.000030517578

Calculation of maximum indicated engine torque

When configured with a turbocharger the maximum filling rlmax_w is specified directly. The maximal filling is now the input variable for the KFMIOP map, in which the optimal torque is stored via speed and filling. The resulting torque mimxl1_w is corrected with the factor FMIVL, which indicates the increase in torque at full load and is obtained the maximum moment mimax_w.

Map KFMIOP converts rlmax_w (from LDRXN) into the torque request, which limits the torque request input to KFMIRL

KFMIOP (Optimal engine torque map)

X axis: engine speed (rpm) 16bit factor 0.25

Y axis: relative air filling (rl_w)/maximum filling (rlmax_w) (%) 16 bit factor 0.0234375

Z axis: KFMIOP (%) 16 bit factor 0.001525878906

Specification for relative load from target torque

The moment milsol_w, which is to be set via the filling path at the base ignition angle and base efficiency, is converted into the moment misopl1_w, which corresponds to the optimal moment at Lambda=1. With the help of the KFMIRL map we get the relative filling that belongs to this working point.

This filling is limited to the minimum permissible value rlmin_w and to the maximum permissible filling rlmax_w (from ldrmx) (This does not exist for naturally aspirated engines) the result is the target filling rlsol_w.

Conversion from rlsol to plsol (target load to target boost pressure) is based on fupsrl_w.

Load is the ratio between the ingested mass and the standard mass in a cylinder.

KFMIRL (Map for calculating target filling)

X axis: engine speed (rpm) 16bit factor 0.25

Y axis: optimal moment at Lambda=1 (%) 16bit factor 0.001525878906

Z axis: KFMIRL (%) 16 bit factor 0.0234375.

KFMIOP and KFMIRL are inverse maps if you change one map you need to change other correspondingly.

Boost pressure deviation

KFDLULS (Delta pressure for overcharge protection diagnosis)

.

X axis: engine speed 8 bit map factor 40

Y axis: Target boost pressure (plsol_w) (hpa) 8 bit factor 10

Z axis: KFDLULS (hpa) 8 bit factor 5

We always recommend to leave this map as it is and modify the boost pid maps accordingly.

If the negative of the Ide is greater than KFDLUS over boost condition will be set.

Where Ide is the boost deviation (setpoint-actual)

If Ide is greater than EDLDRP under boost condition will be set (positive deviation).

KFVPDKLD (Max. permissible pressure ratio DK for ldra diagnosis)

X axis: engine speed 8 bit map factor 40

Y axis: Throttle valve angle related to the lower stop (% DK) 8 bit factor 0.392156862745

Z axis: KFVPDKLD 8 bit factor 0.015625

If pspvds_w is greater than (KFVPDKLD*FVMXLDRA) condition B_lkvdkmn become true. (for leak detection before throttle?)

Where pspvds_w is the ratio intake manifold pressure/pressure before DK.

KFLDIMX (LDR I controller limitation map)

X axis: engine speed (rpm) 16bit factor 0.25

Y axis: Relative target boost pressure LDR (hpa) 16 bit factor 0.0390625

Z axis: KFLDIMX 16 bit factor 0.005